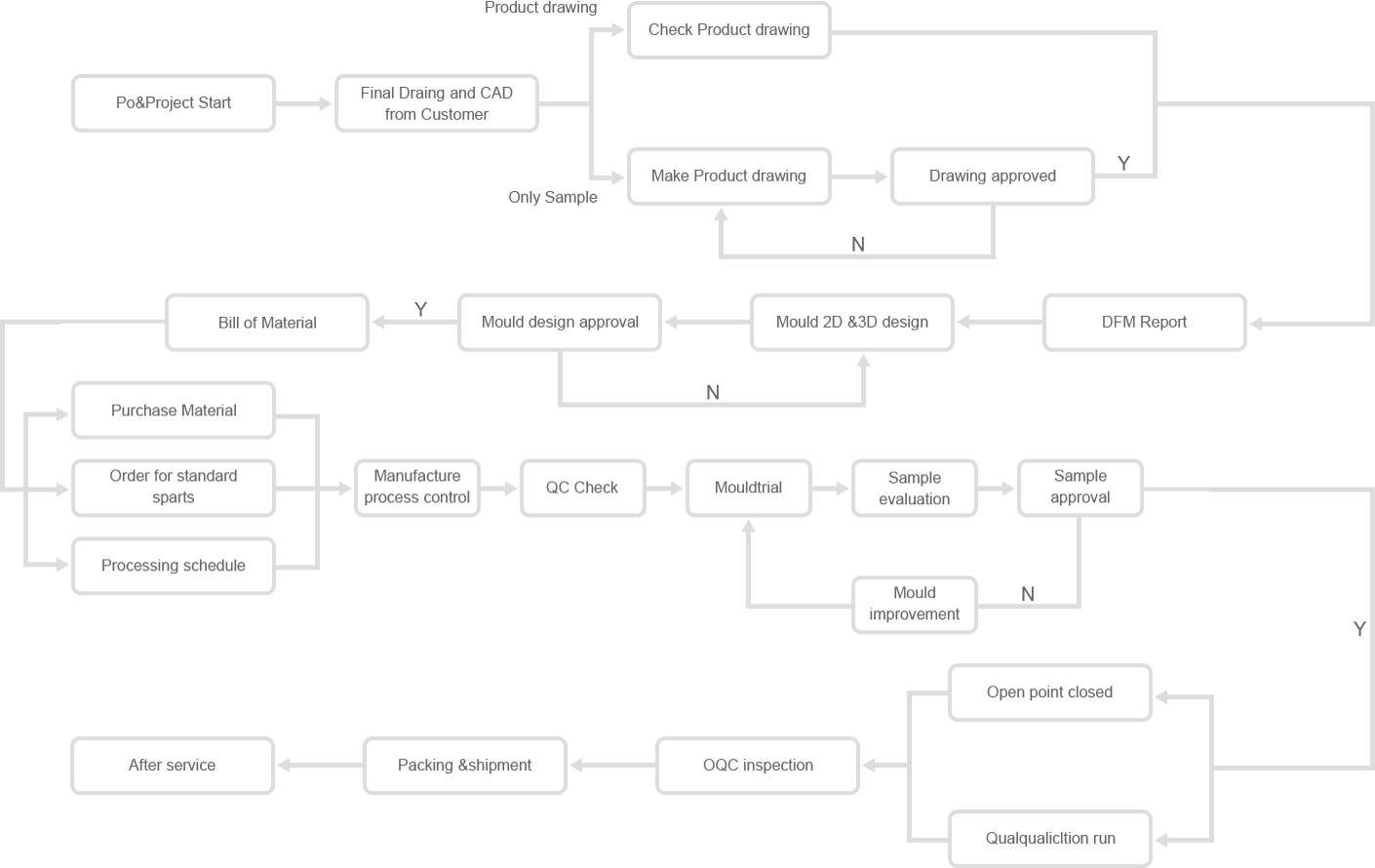

流程图

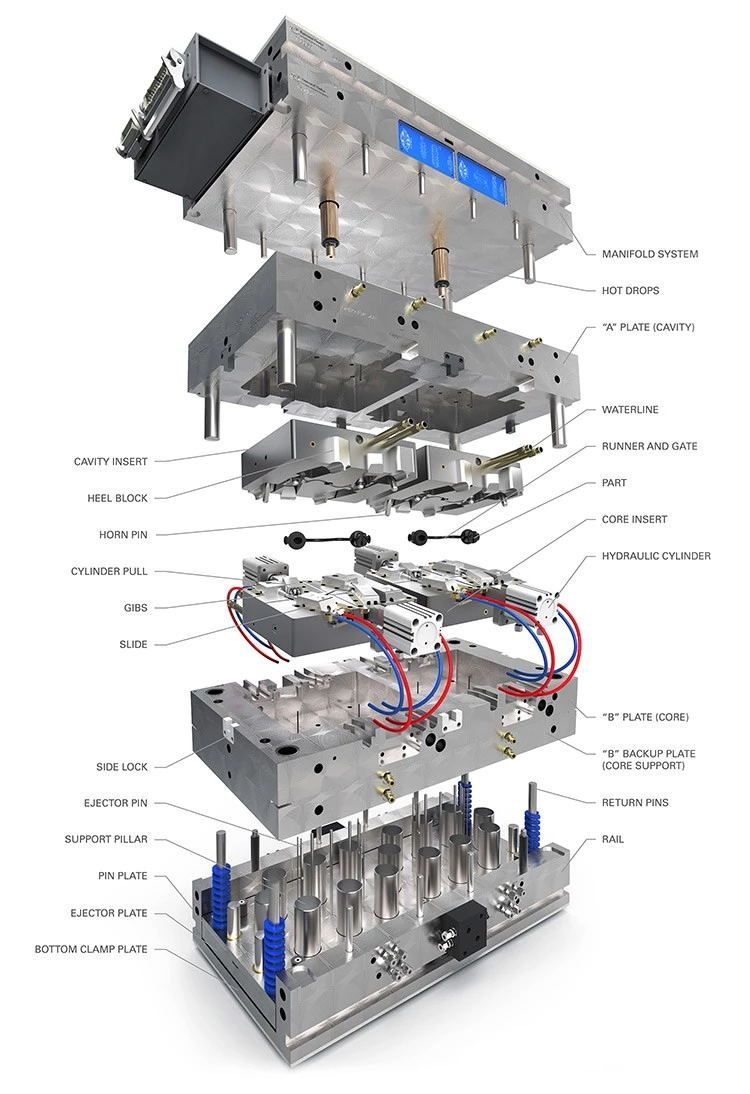

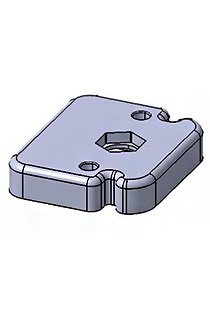

| Mould Type | Plastic Injection Mould |

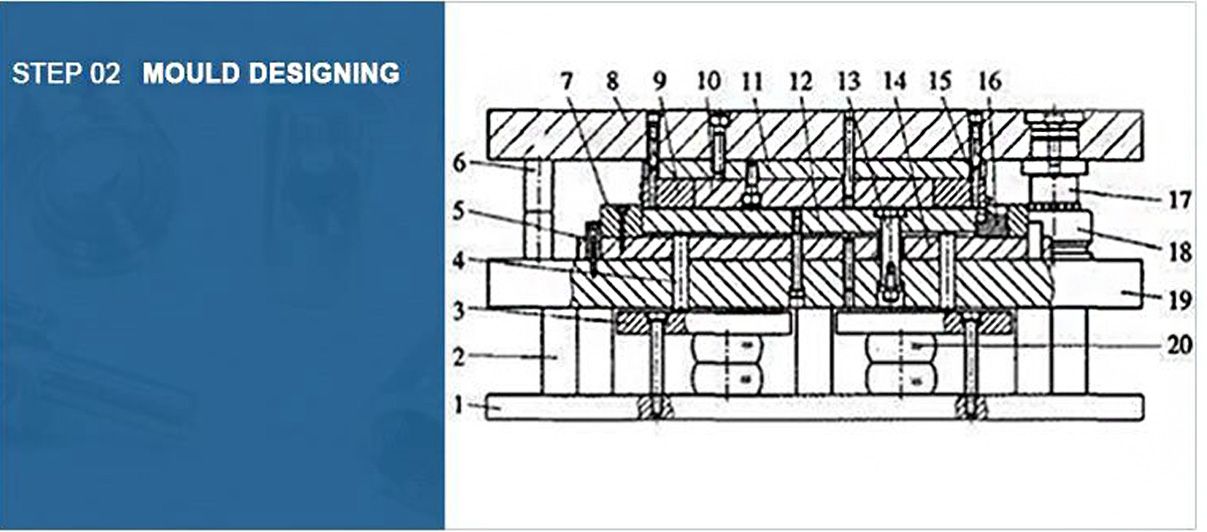

| Design Software | UG, ProE, Auto CAD, Solidworks, etc. |

| Mould Material | 718H, P20, NAK80, S316H, SKD61, SKD11/51/61,SKH-9,S136, ASP60, ASP23, CD650, NAK80,XW-42,2738,8407etc. |

| Hardness of the steel | 20~60 HRC |

| Mould Base | HASCO, DME, LKM, etc. |

| Runner | Hot runner, Cold runner, as per customers requirement and part structure. |

| Mould Cavity | Single-cavity or Multi-cavity, as per customers requirement and part structure. |

| Ejection Techniques | Pin ejection, sleeve ejection, bar ejection, blade ejection, etc. |

| Gate Type | Edge gate, sub-gate, pin gate, side gate, etc. |

| Mould hot treatment | Quencher, Nitridation, Tempering, etc. |

| Mould Cooling System | Water cooling or Beryllium bronze cooling, etc. |

| Mould Surface | EDM, texture, high gloss polishing |

| Mould Life | >500,000 shots |

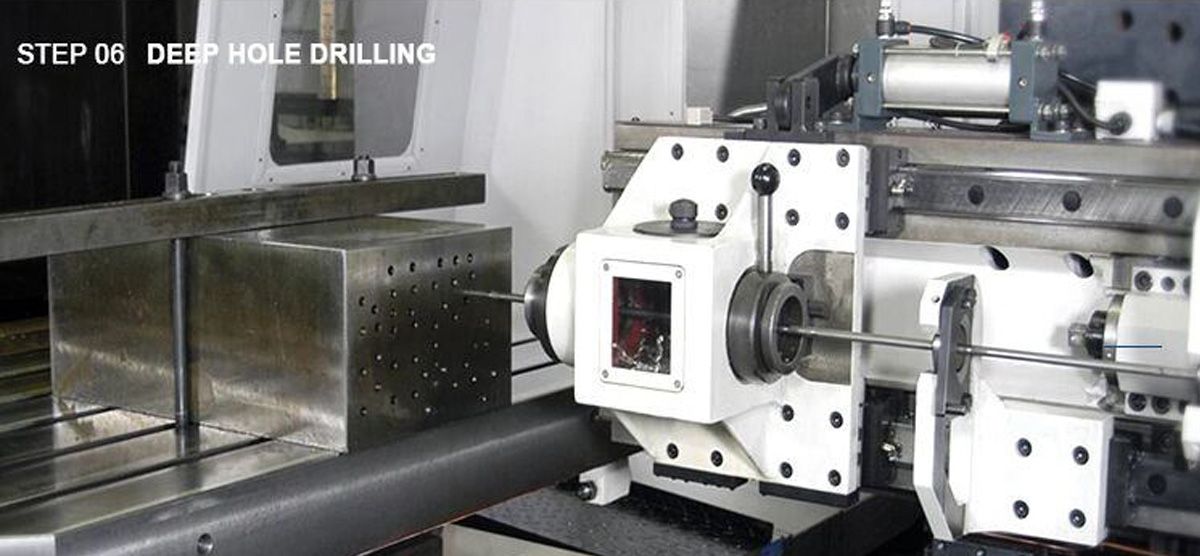

| Process Equipment | CNC machine,Automotive lathe machine,EDM machine,Wire-cutting machine,Milling/Grinding machine,Punching/Drilling machine,Ultrasonic cleaning machine,etc. |

| Lead time | 25~60 days |

| Certificate | ISO 9001:2015 |

| Package | High precision electronic parts plastic mold maker,injection mould,plastic molding.PE bags add export carton for parts,Wooden/Plywood case for mold,or as customer's requests. |

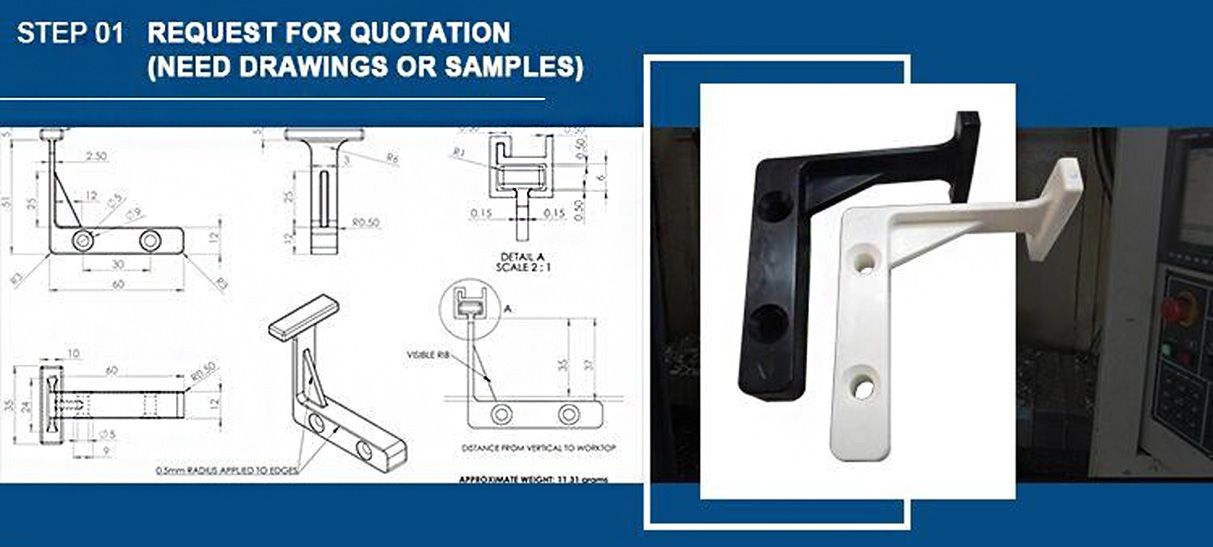

We provide product design service & suggestion as customers' request.

We communicate & exchange the detail information with our customers to make a good mold design.

Manufacturing in-house, we send the mold processing photos and videos to customers.

We start plastic injection parts production after Customers confirm samples.

We can supply assembly service as customers' requests.

Available,such as screen printing, plating, Custom packaging and etc.

1.Over 10 years experience. Free Design, Free CAD and Free existing samples.

2.Factory price makes your cost transparent.

3.Our company has a professional, complete production equipment, Injection Machines total 20 sets, from 60T to 800T. With high precision and top quality. We offer strong engineering support with drawings or samples. Our professional sales and after-sales team , 24 hours on line, can reply your questions within 10 hours.

4.We have our own mould making production line, it’s better for us to control the quality, and improve our effective to shorten the production time.

5.We offer one-step service and after-service.

6.100% strict high quality control.

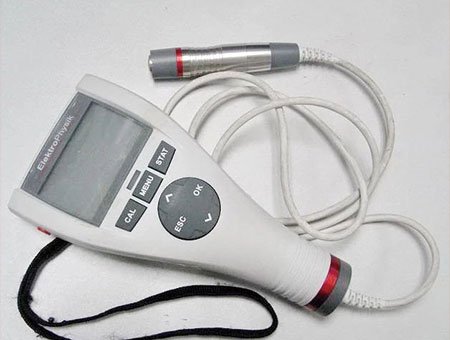

①Raw Material Control: we only use the finest and purest raw material from the worlds premier suppliers, all of which are subject to strict inward quality control checks. And we will test it before mass production.

②In-house QC : Ensuring the quality of our products is at the heart of everything we do. Each individual product is checked carefully by our in-line QC staff prior to being packed, and any that are found to be non compliant are removed and destroyed.

③we accept third part inspection and any other way to supervice the production.

1.Are you factory?

Yes, we are professional manufacturer. Welcome come to visit us and establish long term business relationship and friendship.

2.Which kind products can you do?

We do injection mould and mass production for plastic products. Most plastic products can be customized in our factory.

3.Which kind information need for quotation?

Samples photos with size or 2D3D design, the materials, the weight, the quantity, hot runner or cold runner, mould steel type, the more information the better.

4.I have no 3d drawing, how should I start the project?

You can send us a sample or tell us your detail ideas, we can help you for the 3d design.

5.How long will be the production finished?

Usually 40-45 days, 30-35 days for the mould

6.How about the samples?

We will produce samples and send them to you after the mould finished.

7.How about the modify for the mould?

You can tell us your comments about the samples after you received them. If there is any difference from the drawing, we will modify the mould for free and make new samples for you.